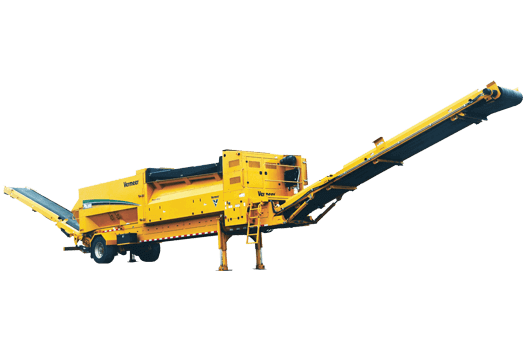

TR5300 Trommel Screen

Ideal for operations where high productivity in a compact size is demanded.

The TR5300 trommel screen is ideal for operations where high productivity in a compact size is demanded. The tensioned screen and drum are designed for optimum productivity, offering simple adjustments and maintenance. The ability for the conveyors to go parallel to the ground gives the operator more control over dust and wind, while also allowing for easier maintenance. The TR5300 features a maintenance access platform for the Deutz TD 2.9L Tier 4 Final (Stage IV), 74 hp (55 kW) engine.

PRODUCT VIDEO

FEATURES & BENEFITS

SPECIFICATIONS

-

Weight32000 lbs

-

Hitch Weight11600 lbs

-

Transport Length39 ft

-

Transport Width98.4 in

-

Transport Height13.4 ft

-

Operation Length89.9 ft

-

Operation Width112.8 in

-

Operation Height15 ft

-

Capacity100 cu yd (76.5 m3) per hr with .5" (12.7 mm) screens installed and material with moisture less than 40%

-

Make and ModelDeutz TD2.9L Tier 4 Final/ Stage IV

-

Number of Cylinders4

-

Engine Rating74 hp (55 kW) @ 2600 rpm and 181 ft-lb (245.4 Nm) of torque @ 1600 rpm

-

Fuel Tank Capacity44 gal

-

Fuel Consumption4.6

-

Maximum Engine Operating Angle (Operating angles do not indicate safe machine operating angles)30 deg

-

Battery950 Cold Cranking Amp Group 31

-

Oil FilterSpin-on

-

Recommended OilMobil 15W40

-

Oil Volume with Filter8.4 qt

-

System Voltage12

-

Air CleanerDual element

-

Radiator FanSuction

-

Tank capacity55 gal

-

Frame DescriptionHeavy Duty Structural Tubing

-

Axle/SuspensionSingle Leaf Sprung

-

Capacity20000 lbs

-

Tires - Option One445/50R22.5

-

Hopper Capacity5.5 cu yd

-

Hopper Bottom Width34 in

-

Hopper Height9.5

-

Hopper Opening34x37

-

Drum Operation0-30.9 gpm (0-117.0 L/min)

-

Drum Diameter5 ft

-

Drum Support DescriptionEight poly trunnion rollers 8" (20.3 cm) diameter 4" (10.2 cm) width

-

Drum Length16 ft

-

Thrust Bearing Diameter4 in

-

Thrust Bearing Face2.9 in

-

Drum Speed0-24 rpm

-

Drum Drive Chain140 custom extended pin

-

Drum Angle Adjustability0-7 degrees

-

Maximum Screen Panels4

-

Brush Diameter14 in

-

Bristle MaterialPolyethylene

-

Brush Assembly SupportTwo 1.25" (3.2 cm) sealed ball bearings

-

Conveyor Operation17 gpm

-

Conveyor Motor Displacement33 cu-in

-

Fines Conveyor Length55 ft

-

Fines Belt Speed500 ft/min

-

Conveyor Belt Width36 in

-

Conveyor Belt Type220 lb, 2 ply, 3/16" x 1/16", R2 splice, Continuous option

-

Conveyor Belt Stacking Height15'

-

Head Pulley TypeRubber lagged, 12" (30.5 cm) diameter, 38" (96.5 cm) wide

-

Head Pulley Bearing2 7/16" (6.2 cm) pillow block

-

Troughing Idler Type20° CEMA "B" with permanently sealed bearings

-

Self-Cleaning Tail Pulley Dimensions10" (25.4 cm) diameter, 38" (96.5 cm) wide with 2.4" (6.1 cm) shaft

-

Head Pulley Takeup10 in

-

Self-Cleaning Return Idlers4" (10.2 cm) rubber disc, qty 8

-

Fines Conveyor Frame2" (5.1 cm) x 8" (20.3 cm) structural steel tubing

-

Overs Conveyor Length10.5 ft

-

Maximum Variable Overs Belt Speed350 ft/min

-

Conveyor Belt Size36

-

Conveyor Belt Type220 lb, 2 ply, 3/16" x 1/16", R2 splice, Continuous option

-

Conveyor Belt Stacking Height6'

-

Head Pulley TypeRubber lagged, 12" (30.5 cm) diameter, 38" (996.5 cm) wide

-

Head Pulley Bearing2 7/16" (6.2 cm) pillow block

-

Self-Cleaning Tail Pulley Dimensions10" (25.4 cm) diameter, 38" (96.5 cm) wide with 2.4" (6.1 cm) shaft

Talk with a Vermeer expert today!

Fill the next form with your informations and in the fastest time an Vermeer representant will contact you .