TG5000E Tub Grinder

As your stationary operation looks to electric-power, Vermeer is your partner for the equipment expertise you need.

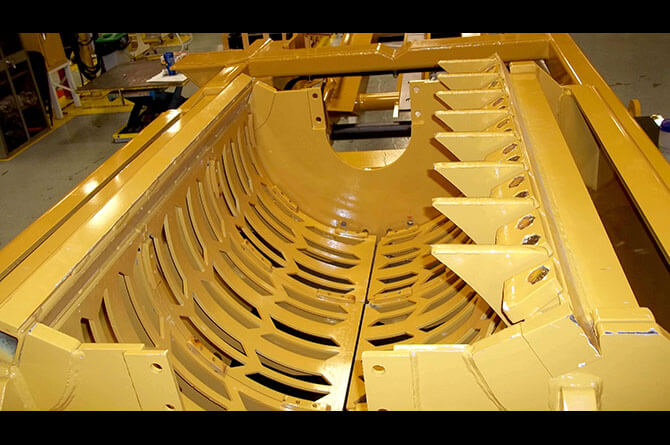

As your stationary operation looks to electric-power, Vermeer is your partner for the equipment expertise you need. The TG5000E tub grinder is equipped with a 500-hp (373-kW) motor to provide power to the mill. With the option to configure either a soft-start or VFD starter panel – along with Vermeer features like the duplex drum design and continuous undermill discharge conveyor system – the TG5000E has the flexibility and features you need for productive processing.

PRODUCT VIDEO

FEATURES & BENEFITS

SPECIFICATIONS

-

Maximum Length - Transport8.9 m

-

Maximum Length - Conveyor Unfolded15.6 m

-

Maximum Width (Transport)2.5 m

-

Maximum Height (Transport)3.6 m

-

Weight - Engine Option One19087.2 kg

-

Front Mount Pad Weight (Operation)6713.2 kg

-

Rear Mount Pad Weight (Operation)13902.6 kg

-

Make and ModelWEG W22

-

Gross Horsepower (Maximum)372.8 kw

-

Torque (Max)1967.3 Nm

-

Cooling MediumAir

-

Torque LimiterPT Tech - Continuously engaged, friction type

-

ManufacturerWeg W22

-

FrameNEMA 145T

-

Horsepower1.5 kw

-

Voltage460

-

Frequency60

-

Phase3

-

Rated Speed1750 rpm

-

EnclosureTEFC

-

Full Load Amps2.61

-

Locked Rotor Amps19.6

-

Service Factor1.25

-

Duty CycleS1

-

NEMA DesignB

-

Insulation ClassF

-

Full Load Torque8 Nm

-

Locked Rotor (%)240%

-

Break Down300%

-

Ambient Temperature1352 f

-

Nominal Efficiency86.5 (NEMA Premium Efficiency)

-

Power Factor0.84

-

Approximate Weight23.1 kg

-

Added ItemsTerminal Block, NEMA C-Face Mount

-

Drive TypeDirect

-

ManufacturerWeg W22

-

FrameNEMA 364/5TS

-

Horsepower44.7 kw

-

Voltage460

-

Frequency60

-

Phase3

-

Rated Speed1775 rpm

-

EnclosureTEFC

-

Full Load Amps68.3

-

Locked Rotor Amps451

-

Service Factor1.25

-

Duty CycleS1

-

NEMA DesignB

-

Insulation ClassF

-

Full Load Torque237.3 Nm

-

Locked Rotor (%)240%

-

Break Down260%

-

Ambient Temperature1352 f

-

Nominal Efficiency95 (NEMA Premium Efficiency)

-

Power Factor0.87

-

Approximate Weight394.2 kg

-

Added ItemsTerminal Block, NEMA C-Face Mount, Short Shaft

-

Drive TypeDirect

-

Height236.2 cm

-

Width302.3 cm

-

Depth71.1 cm

-

Weight1369.8 kg

-

Tub Table Thickness1 cm

-

Tub Table TypeT1 Steel

-

Table Tilt Degrees91 deg

-

Millbox Opening24.2" x 47.9" (61.4 cm x 121.5 cm)

-

Inside Diameter of Tub2.4 m

-

Inside Flare Diameter - At Base of Tub2.5 m

-

Inside Flare Diameter - At Tub Opening3.7 m

-

Depth of Tub1.5 m

-

Tub Capacity8.6 cm

-

Wall Thickness.6 cm

-

Wall TypeT1 Steel

-

Loading Height3.2 m

-

Drive TypeContinuous sprocket

-

Drive Chain120H roller chain

-

Drive TensionerStandard

-

Drive MotorOpen loop

-

Tub Roller Quantity8 carrier, 8 guide (16 total)

-

Tub Speed10 rpm

-

Tub Agitators4

-

Thrown Object Restraint SystemPivoting tub cover assembly

-

Tub Cover DescriptionHydraulically activated

-

Tub Cover Positions2

-

Rotor DeflectorStandard

-

Falling Object Protection at Control StationOverhead and side protection

-

Millbox Opening24" x 47.9" (61.4 cm x 121.5 cm)

-

Drum Diameter57.2 cm

-

Tip Diameter72.6 cm

-

Drum Cutting Width116.8 cm

-

Drum Skin Thickness4.4 cm

-

Drum Speed1785 rpm

-

Bearing Typespherical roller

-

Number of Hammers8

-

Number of Cutters16

-

Cutter Block TypesBlock style single bolt wide 3" x 3.5" (7.6 cm x 8.9 cm) wide; 2-bolt 2" x 3" (5.1 cm x 7. 6 cm) narrow

-

Center Retention Pin Dimensions2" (5.1 cm)

-

Number of Wipers2

-

Screen Weight181.4 kg

-

Screen Dimensions49.5" x 28.5" x 14.9" (126 cm x 72.4 cm x 37.8 cm)

-

Screen TypeFabricated from abrasion resistant steel (qty 2)

-

Breaker Bar TypeT1 steel, replaceable

-

Breaker Bar Dimensions2.5" x 3" (6.4 cm x 7.6 cm)

-

Screen Area17509.6 sq cm

-

Distance - Screen to Millbox Wall27.9 cm

-

Length7.3 m

-

Width91.4 cm

-

Belt DesignOne piece, 330# with V-cleat

-

SpliceFlexco R2 stainless steel

-

Return Roller Quantity5 standard and 1 vibrating roller

-

Idler Roller Diameter20.3 cm

-

Standard Drive Roller Diameter32.5 cm

-

Magnetic Drive Roller Diameter32.5 cm

-

Drive MotorGeroler

-

Belt Speed195.1 m/min

-

Load Height4.3 m

-

Tank capacity359.6 L

-

Recommended OilHy-Power 68

-

Filtration MethodIn-tank return filters (qty 2)

-

Number of Coolers1

-

System TypeOpen loop

-

Pump TypeGear

-

Pump Flow at Maximum RPM72.7 L/min

-

System relief pressure193.1 bar

-

System TypeOpen loop

-

Pump TypeGear

-

Pump Flow at Maximum RPM72.7 L/min

-

System relief pressure193.1 bar

-

System Voltage24 VDC

-

System ProtectionFused

-

Display TypeAnalog hydraulic gauges, LCD multifunction

-

Machine InformationYes

-

Operational FaultsYes

-

GaugesAuxiliary hydraulic system pressure, tub rotation hydraulic system pressure, conveyor hydraulic system pressure

-

SwitchesMoisture proof, toggle switch

-

Display TypeLCD multifunction

-

Engine InformationMotor start/stop

-

Motor InformationYes

-

Machine InformationYes

-

Operational FaultsYes

-

SwitchesSealed membrane

-

Operating Range300' (91.4 m)

-

Battery TypeAA (qty 6)

-

Channel Setting50 channels

-

Frame DescriptionContinuous I-beam

-

ScreensOptional

-

Special Tools GroupOptional

-

Special PaintOptional

-

Extended WarrantyOptional

-

Preventative MaintenanceOptional

Talk with a Vermeer expert today!

Fill the next form with your informations and in the fastest time an Vermeer representant will contact you .