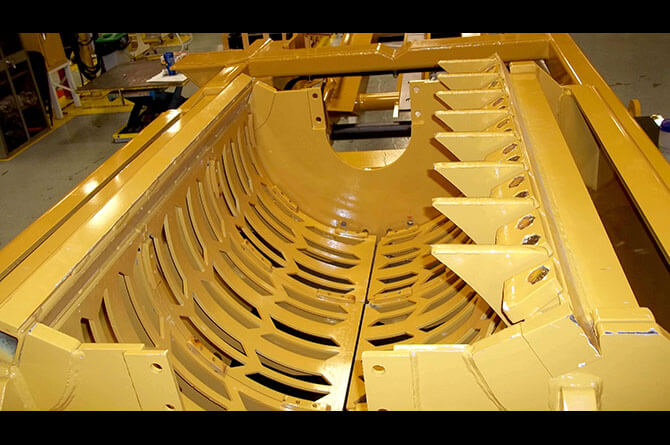

TG5000E TOCATOR CU CUVA

Deoarece operatiunea dvs. stationara este alimentata cu energie electrica, Vermeer este partenerul dvs. pentru echipamentul de care aveti nevoie.

Deoarece operatiunea dvs. stationara este alimentata cu energie electrica, Vermeer este partenerul dvs. pentru echipamentul de care aveti nevoie. Masina de tocat TG5000E este echipata cu un motor de 500 CP (373-kW) pentru a furniza energie morii. Cu optiunea de a configura fie un panou de pornire soft-start, fie VFD - impreuna cu caracteristicile Vermeer, cum ar fi proiectarea tamburului duplex si sistemul transportor continuu cu descarcare de sub moara, TG5000E are flexibilitatea si caracteristicile de care aveti nevoie pentru procesarea productiva.

VIDEOCLIP PRODUS

CALITĂȚI & BENEFICII

SPECIFICAȚII

-

Maximum Length - Transport8.9 m

-

Maximum Length - Conveyor Unfolded15.6 m

-

Maximum Width (Transport)2.5 m

-

Maximum Height (Transport)3.6 m

-

Weight - Engine Option One19087.2 kg

-

Front Mount Pad Weight (Operation)6713.2 kg

-

Rear Mount Pad Weight (Operation)13902.6 kg

-

Make and ModelWEG W22

-

Gross Horsepower (Maximum)372.8 kw

-

Torque (Max)1967.3 Nm

-

Cooling MediumAir

-

Torque LimiterPT Tech - Continuously engaged, friction type

-

ManufacturerWeg W22

-

FrameNEMA 145T

-

Horsepower1.5 kw

-

Voltage460

-

Frequency60

-

Phase3

-

Rated Speed1750 rpm

-

EnclosureTEFC

-

Full Load Amps2.61

-

Locked Rotor Amps19.6

-

Service Factor1.25

-

Duty CycleS1

-

NEMA DesignB

-

Insulation ClassF

-

Full Load Torque8 Nm

-

Locked Rotor (%)240%

-

Break Down300%

-

Ambient Temperature1352 f

-

Nominal Efficiency86.5 (NEMA Premium Efficiency)

-

Power Factor0.84

-

Approximate Weight23.1 kg

-

Added ItemsTerminal Block, NEMA C-Face Mount

-

Drive TypeDirect

-

ManufacturerWeg W22

-

FrameNEMA 364/5TS

-

Horsepower44.7 kw

-

Voltage460

-

Frequency60

-

Phase3

-

Rated Speed1775 rpm

-

EnclosureTEFC

-

Full Load Amps68.3

-

Locked Rotor Amps451

-

Service Factor1.25

-

Duty CycleS1

-

NEMA DesignB

-

Insulation ClassF

-

Full Load Torque237.3 Nm

-

Locked Rotor (%)240%

-

Break Down260%

-

Ambient Temperature1352 f

-

Nominal Efficiency95 (NEMA Premium Efficiency)

-

Power Factor0.87

-

Approximate Weight394.2 kg

-

Added ItemsTerminal Block, NEMA C-Face Mount, Short Shaft

-

Drive TypeDirect

-

Height236.2 cm

-

Width302.3 cm

-

Depth71.1 cm

-

Weight1369.8 kg

-

Tub Table Thickness1 cm

-

Tub Table TypeT1 Steel

-

Table Tilt Degrees91 deg

-

Millbox Opening24.2" x 47.9" (61.4 cm x 121.5 cm)

-

Inside Diameter of Tub2.4 m

-

Inside Flare Diameter - At Base of Tub2.5 m

-

Inside Flare Diameter - At Tub Opening3.7 m

-

Depth of Tub1.5 m

-

Tub Capacity8.6 cm

-

Wall Thickness.6 cm

-

Wall TypeT1 Steel

-

Loading Height3.2 m

-

Drive TypeContinuous sprocket

-

Drive Chain120H roller chain

-

Drive TensionerStandard

-

Drive MotorOpen loop

-

Tub Roller Quantity8 carrier, 8 guide (16 total)

-

Tub Speed10 rpm

-

Tub Agitators4

-

Thrown Object Restraint SystemPivoting tub cover assembly

-

Tub Cover DescriptionHydraulically activated

-

Tub Cover Positions2

-

Rotor DeflectorStandard

-

Falling Object Protection at Control StationOverhead and side protection

-

Millbox Opening24" x 47.9" (61.4 cm x 121.5 cm)

-

Drum Diameter57.2 cm

-

Tip Diameter72.6 cm

-

Drum Cutting Width116.8 cm

-

Drum Skin Thickness4.4 cm

-

Drum Speed1785 rpm

-

Bearing Typespherical roller

-

Number of Hammers8

-

Number of Cutters16

-

Cutter Block TypesBlock style single bolt wide 3" x 3.5" (7.6 cm x 8.9 cm) wide; 2-bolt 2" x 3" (5.1 cm x 7. 6 cm) narrow

-

Center Retention Pin Dimensions2" (5.1 cm)

-

Number of Wipers2

-

Screen Weight181.4 kg

-

Screen Dimensions49.5" x 28.5" x 14.9" (126 cm x 72.4 cm x 37.8 cm)

-

Screen TypeFabricated from abrasion resistant steel (qty 2)

-

Breaker Bar TypeT1 steel, replaceable

-

Breaker Bar Dimensions2.5" x 3" (6.4 cm x 7.6 cm)

-

Screen Area17509.6 sq cm

-

Distance - Screen to Millbox Wall27.9 cm

-

Length7.3 m

-

Width91.4 cm

-

Belt DesignOne piece, 330# with V-cleat

-

SpliceFlexco R2 stainless steel

-

Return Roller Quantity5 standard and 1 vibrating roller

-

Idler Roller Diameter20.3 cm

-

Standard Drive Roller Diameter32.5 cm

-

Magnetic Drive Roller Diameter32.5 cm

-

Drive MotorGeroler

-

Belt Speed195.1 m/min

-

Load Height4.3 m

-

Tank capacity359.6 L

-

Recommended OilHy-Power 68

-

Filtration MethodIn-tank return filters (qty 2)

-

Number of Coolers1

-

System TypeOpen loop

-

Pump TypeGear

-

Pump Flow at Maximum RPM72.7 L/min

-

System relief pressure193.1 bar

-

System TypeOpen loop

-

Pump TypeGear

-

Pump Flow at Maximum RPM72.7 L/min

-

System relief pressure193.1 bar

-

System Voltage24 VDC

-

System ProtectionFused

-

Display TypeAnalog hydraulic gauges, LCD multifunction

-

Machine InformationYes

-

Operational FaultsYes

-

GaugesAuxiliary hydraulic system pressure, tub rotation hydraulic system pressure, conveyor hydraulic system pressure

-

SwitchesMoisture proof, toggle switch

-

Display TypeLCD multifunction

-

Engine InformationMotor start/stop

-

Motor InformationYes

-

Machine InformationYes

-

Operational FaultsYes

-

SwitchesSealed membrane

-

Operating Range300' (91.4 m)

-

Battery TypeAA (qty 6)

-

Channel Setting50 channels

-

Frame DescriptionContinuous I-beam

-

ScreensOptional

-

Special Tools GroupOptional

-

Special PaintOptional

-

Extended WarrantyOptional

-

Preventative MaintenanceOptional

Contactați un expert Veerem!

Completează formularul cu datele tale și în cel mai scurt timp un reprezentant Vermeer vă va contacta .