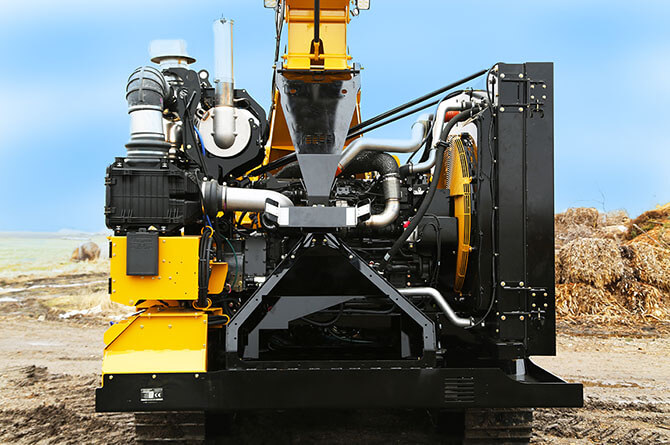

WC2500TX Whole Tree Chipper

Tracked undercarriage allows you to maneuver in the woods and tough land-clearing sites.

The WC2500TX whole tree chipper has a tracked undercarriage, allowing you to maneuver in the woods and tough land-clearing sites. Featuring a microchip or macrochip drum with adjustable bite sizes, faster and easier knife setup and a PT Tech clutch, the WC2500TX whole tree chipper offers a powerful and effective solution for producing wood chips in a compact footprint. Material can be handled efficiently with variable-speed dual-infeed conveyor chains and SmartCrush technology.

PRODUCT VIDEO

FEATURES & BENEFITS

SPECIFICATIONS

-

Maximum Length (Operation)8.7 m

-

Maximum Length - Transport8 m

-

Maximum Width (Transport)299.7 cm

-

Maximum Height (Transport)3.5 m

-

Weight - Engine Option Two21999.2 kg

-

Sound Power122

-

Make and ModelCummins QSX15 Tier 4 Final

-

Number of Cylinders6

-

Gross Horsepower (Maximum)447.4 kw

-

Torque (Max)2779.4 Nm

-

Fuel Tank Capacity757.1 L

-

Max Fuel Consumption117.3 lph

-

Fuel TypeUltra-low sulfur diesel

-

Air CleanerTwo-stage direct flow

-

Oil FilterSpin-on

-

Recommended OilCES 20078 or 20081

-

Oil Volume with Filter49.2 L

-

Maximum Angle of Continuous Operation45 deg

-

Cooling MediumLiquid

-

Coolant Capacity (Engine and Radiator)87.1 L

-

Alternator105

-

FanReversible

-

Clutch TypePT Tech electronically controlled dry

-

Clutch Drive EngagementHydraulic

-

Make and ModelCummins QSX15 Tier 3

-

Number of Cylinders6

-

Gross Horsepower (Maximum)447.4 kw

-

Torque (Maximum)2542.2 Nm

-

Fuel Tank Capacity757.1 L

-

Max Fuel Consumption117.3 lph

-

Fuel TypeUltra-low sulfur diesel

-

Air CleanerTwo-stage direct flow

-

Oil FilterSpin-on

-

Recommended OilCES 20078 or 20081

-

Oil Volume with Filter49.2 L

-

Maximum Angle of Continuous Operation45 deg

-

Cooling MediumLiquid

-

Coolant Capacity (Engine and Radiator)87.1 L

-

Alternator100

-

FanReversible

-

Clutch TypePT Tech electronically controlled dry

-

Clutch Drive EngagementHydraulic

-

Material Capacity63.5 cm

-

Thickness1.3 cm

-

Width86.4 cm

-

Diameter91.4 cm

-

Speed1169 rpm

-

Weight With Shaft1434.7 kg

-

Safety Lock - Number of Positions2 to 4

-

TypeAdjustable

-

Knife Thickness1.6 cm

-

MaterialA8 chipper steel

-

Useable Edges1

-

Knife Size8.5 or 17

-

Number of Bolts/Knife4 or 5

-

Replaceable Threaded Knife BlockHex nut

-

Fixture MethodBolt

-

Bedknife Size34" wide

-

Bedknife Thickness3.8 cm

-

Bedknife MaterialCold-formed low-carbon bar

-

Bedknife - Number of Useable Edges2

-

Number of Pockets2 or 4

-

Replaceable Wear PlatesYes

-

Number of Replaceable Wear Plates8

-

Number of Bearings2

-

Bore13.8 cm

-

Type

-

Manufacturer

-

Dynamic Capacity

-

Static Capacity

-

Belt Idler/Tensioner

-

Belt Type

-

Infeed Roller Width86.4 cm

-

Maximum Feed Height68.6 cm

-

Infeed Roller Weight260.8 kg

-

Infeed Roller Diameter71.1 cm

-

Tooth DesignStraight knives

-

Drive MotorWS-series

-

Drive PlanetaryAuburn Model 9

-

Drive Displacement113.1 cu-cm

-

Drive ManufacturerWhite

-

Feed Roller Down Pressure1530

-

Feed Roller OrientationHorizontal

-

Number of Feed RollersOne upper, one conveyor

-

Number of Knives12

-

Feed Roller Distance to Drum2.5 cm

-

Feed Roller Speed29.9 m/min

-

Chute Height335.3 cm

-

Bottom Thickness.3 cm

-

Bottom Replaceable Wear PlateAR 400

-

Wear Plate Thickness.5 cm

-

Top Thickness.5 cm

-

Side Wall Thickness.5 cm

-

Deflector Thickness.5 cm

-

Rotation TypeHydraulic

-

Rotational LockHydraulic

-

Side Deflector Angle14 deg

-

Up Deflector Angle22 deg

-

Down Deflector Angle14 deg

-

Chute Height494 cm

-

Bottom Thickness.3 cm

-

Wear Plate Thickness.5 cm

-

Top Thickness.5 cm

-

Side Wall Thickness.5 cm

-

Deflector Thickness.5 cm

-

Up Deflector Angle18 deg

-

Down Deflector Angle90 deg

-

Tank capacity124.9 L

-

Recommended Oil TypeHy-Power 68, 46, or 32

-

System TypeOpen-center

-

Filtration MethodIntake suction screens and return filter

-

Pump Flow at Maximum RPM60.6 L/min

-

System relief pressure275.8 bar

-

Auto Reverse PSI258.6 bar

-

Flow ControlTwo - feed roller and infeed conveyor

-

Oil Cooler1

-

Frame Description8" x 4" x .375" wall rectangular tubing

-

Toolbox DescriptionLockable

-

Brake TypeAir

-

Trailer Light TypeLED

-

Track pad width50.8 cm

-

Track Gauge246.4 cm

-

Track Pitch335.3 cm

-

Ground pressure.6 bar

-

Special PaintYes

-

Extended WarrantyYes

-

Adjustable Height Discharge ChuteNo

-

Feed Table Width248.9 cm

-

Feed Table Length - Option One3

-

Feed Conveyor TypeDual independent chain

-

Material Construction.50" thick

-

Infeed Floor ConstructionAR400 wear plate

-

Infeed Slope6 deg

-

Number of Infeed Chains2

-

Replaceable Chain SlidesYes

Talk with a Vermeer expert today!

Fill the next form with your informations and in the fastest time an Vermeer representant will contact you .