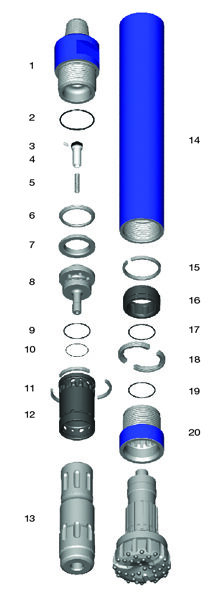

Ciocan hidraulic Mincon MP90

Ciocanul hidraulic Mincon MP90 este proiectat folosind tehnologie dovedita a fi cu performanta de top acest lucru clasandu-se intre primele locuri, atunci cand le comparam cu alte utilaje similare din piață. Aceste instrumente sunt excelente pentru toate tipurile de foraj, incepand de la foraj pentru instalatiii geotermale rezidențiale, forajul pentru carierele de producție piatra, foraje seismice și foraje pentru construcții mici.

Caracteristici și beneficii cheie

- Funcțiile patentate maximizează producția și reduc la minim partea de servisare

- Datorita faptului ca nu are foarte multe componente interne nici piesele de schimb nu sunt foarte numeroase

- Designul fără valve asigură o funcționare lina si optimizeaza procesul pentru o utilizare frecventa

- Manșon pentru o rezistență optimă la uzură chiar și în cele mai vitrege si abrazive condiții.

- Pozitionarea sistemului de montare in spatele ciocanului usureaza montarea si demontarea acestuia

- Pozitionarea furtunelor, elimină nevoia de haine de schimb și instrumente speciale de asamblare.

- Toate componentele interne critice sunt tratate termic sub control strict pentru a maximiza longevitatea uneltei.

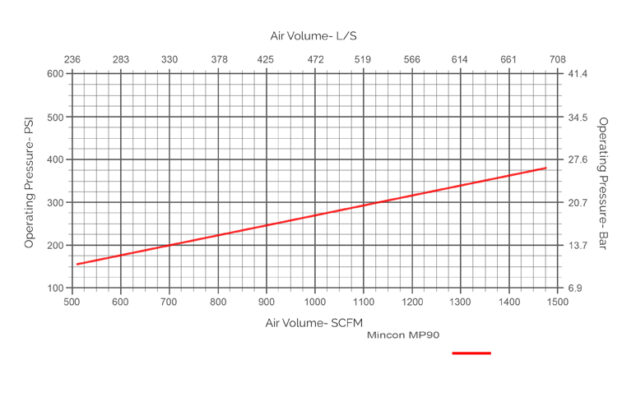

Air Pressures are given for compressors operating at seal level at 20° C (68º F). Corrections to actual compressor volume should be made to account for temperature, altitude and relative humidity.

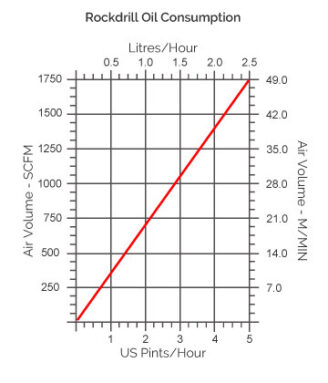

DTH hammers must receive a constant supply of proper rock drill oil to protect the internal components and to provide a good air seal between the hammer's running surfaces for efficient drilling. Mincon recommends the use of Mincon Envirosafe® Rock Drill Oil (RDO) to maintain optimal performance and extend the life of the internal components. The correct consumption of oil is dependent upon the air volume and conditions. Please refer to the lubrication graph below for recommendations. When drilling in wet conditions the normal amount should be doubled. There should be visual evidence of oil around the drill bit shank and within the tube joints when changing tubes.

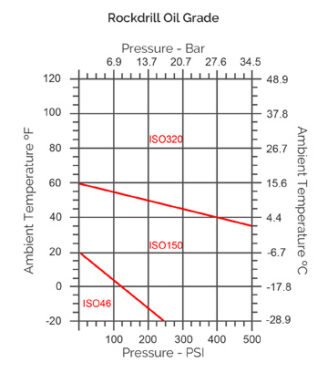

If using petroleum based rock drill oils, the recommended grade of oil is dependent on the ambient temperature and the operating pressure. As a rule of thumb, ISO320 grade rock drill oil should be used whenever possible as the hammer is a high frequency tool, however, where the pump cannot pump the oil in colder conditions, a lower grade of oil can be used as per the graph below.